Energy

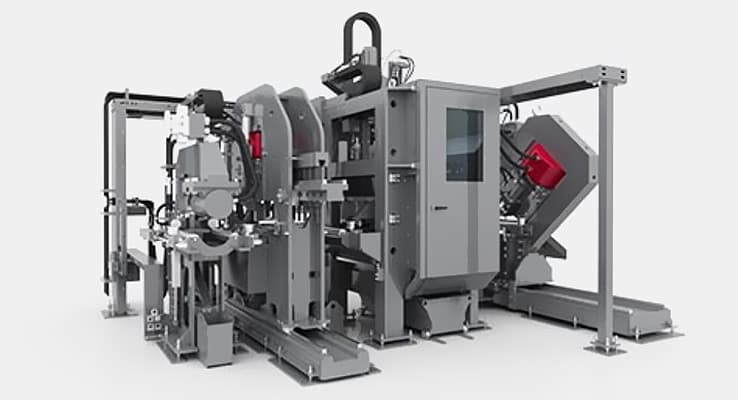

D3Touch from welding alloys is a touchscreen-based control technology that automates fully automated welding techniques. Welding Alloys incorporates new technology in all Welding Alloys equipment, improving the performance and accuracy of the weld process. This technology compliments our precision engineering mechanics and results in maximum performance.